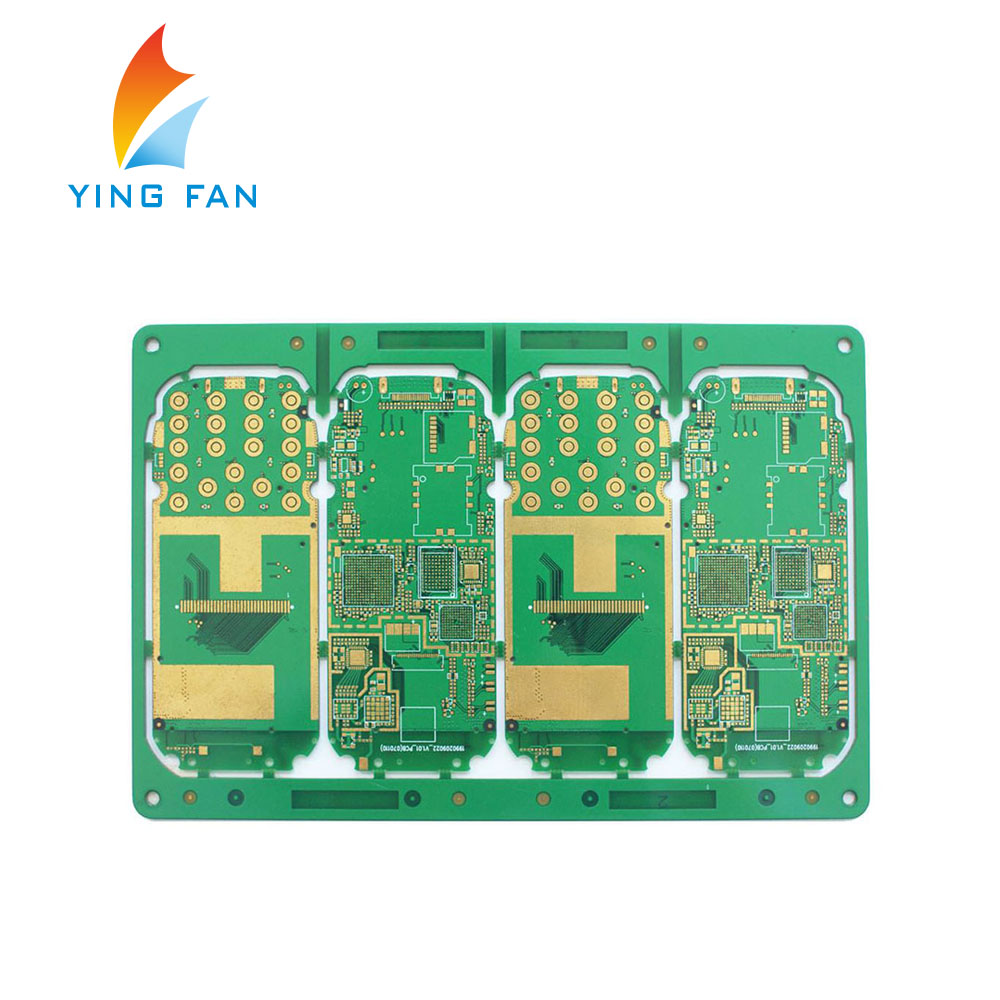

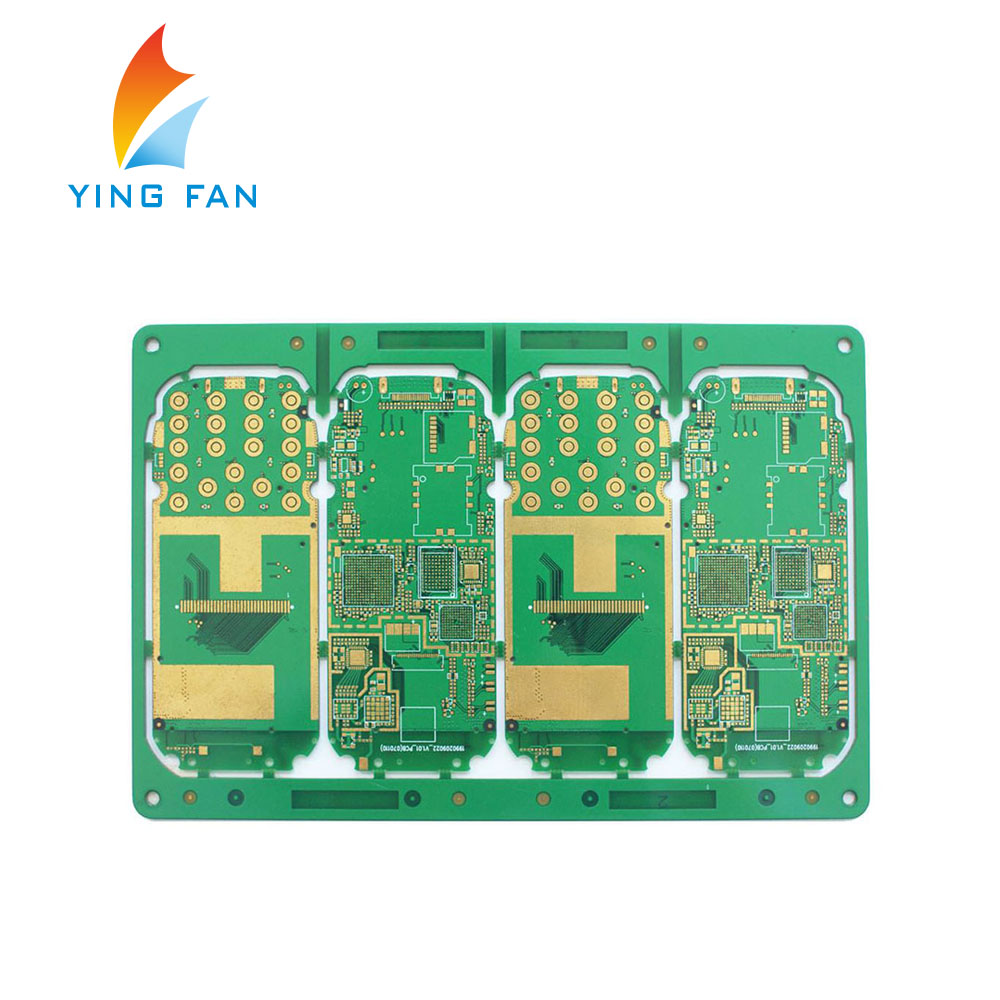

1. While achieving low defect rate and high output, it can achieve the stable production of HDI PCB 's conventional high-precision operation.

In terms of imaging, this type of design requires the ring width to be less than 75µm, and in some cases the ring width is even less than 50µm. Due to alignment issues, these inevitably lead to low production. In addition, driven by miniaturization, lines and pitches are getting finer and thinner—satisfying this challenge requires a change in traditional imaging methods. This can be done by reducing the panel size, or by using a shutter exposure machine to image the panel in several steps (four or six). Both of these methods achieve better alignment by reducing the influence of material deformation. Changing the panel size has resulted in high material costs, and the use of shutter exposure machines has resulted in low daily output. Neither of these two methods can completely solve the material deformation and reduce the defects related to the photographic plate, which includes the actual deformation of the photographic plate when printing a batch/batch.

2. To achieve the required output by printing the required number of HDI PCBs every day. As mentioned earlier, the relevant quantity of the required output should be taken into account in the accuracy requirements. To achieve the required output, automatic control is needed to obtain a high output rate.

3. Low cost operation. This is the main requirement for any mass manufacturer. The early LDI mode either required the traditional use of dry film to be replaced with a more sensitive dry film to achieve faster imaging speed; or according to the light source used in the LDI mode, the dry film was changed to a different waveband. In all these cases, the new dry film is usually more expensive than the traditional dry film used by the manufacturer.

4. Compatible with existing processes and production methods. The processes and methods of mass production are usually carefully regulated to meet mass production requirements. The introduction of any new imaging method should have minimal changes to existing methods. This includes minimal changes in the dry film used, the ability to expose each layer of the solder mask, the traceability function required for mass production, and more.